|

Packaging Products was featured in an AIAG video about the benefits of their Small Supplier Membership Program. Please click on the link below to view the video on their YouTube channel:

https://youtu.be/uSaVZsNBv_w For U.S. Navy planes, it is essential that tools are always organized and accounted for. The reason for this is to avoid a forgotten tool that, if left in the engine, can cause a disaster.

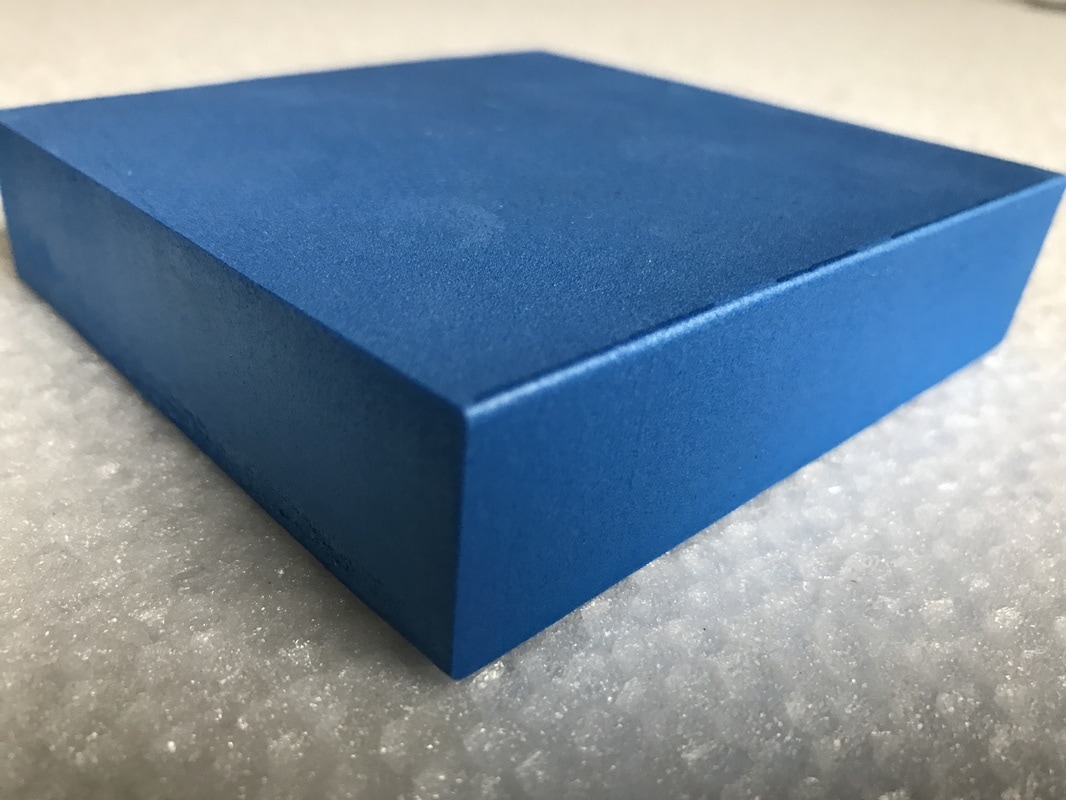

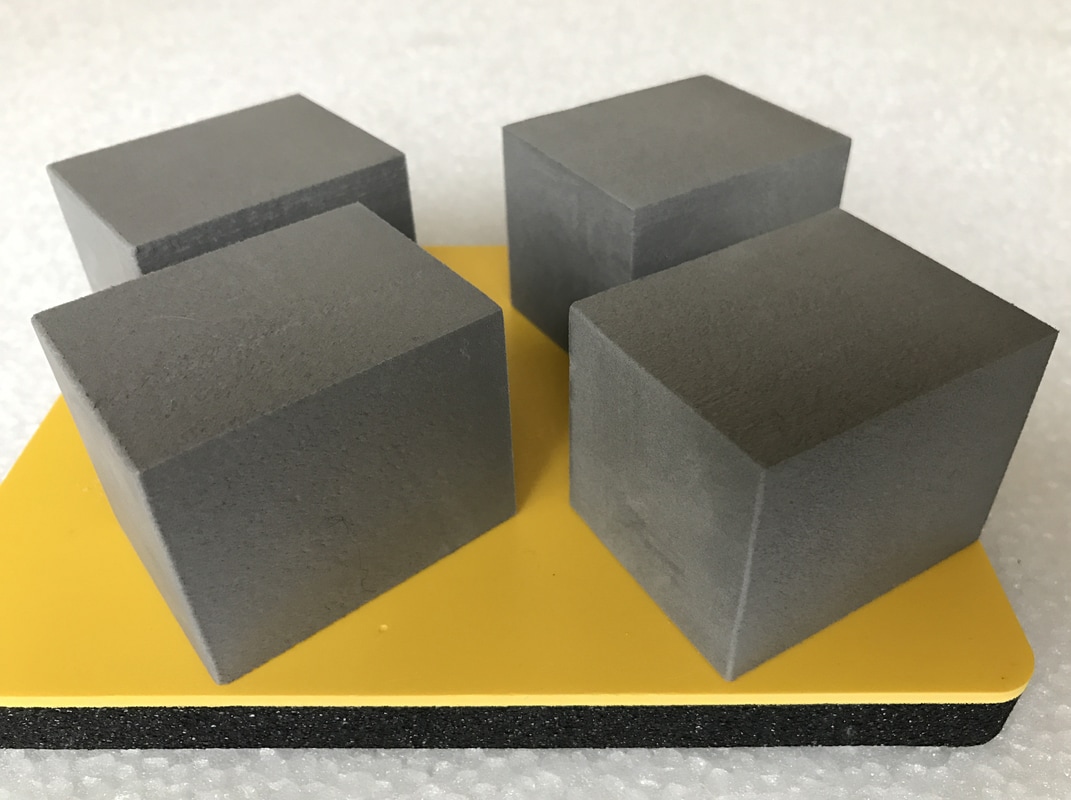

Packaging Products received a contract to provide the foam for a Navy tool organizer that allows for quick verification that all tools are exactly where they need to be. If something is missing, it will be immediately obvious. We used a 4-pound cross linked foam and brought the job in under the cost previously established. Fighters take a beating; not just from each other but from the ring itself. Packaging Products created a one-inch foam pad that delivered a spring cushioning to soften falls and protect the body.

Unique about this product was the need to square up the foam pieces to match the tiles that make up the 12-inch floor. The success of this solution was our ability to deliver thickness tolerance, tight size control and a lower price. Packaging Products is a Tier Two supplier for Toyota who needed a foam solution for the car trunk where the spare tire is stored. We used a four pound cross linked foam to create a space saver used to accommodate the space where the tire would sit.

We were awarded the project because we could provide the critical tolerance required, whereas the previous supplier could not. Our ability to hold tighter tolerances is a significant differentiator for Packaging Products. This product is currently in production throughout the Toyota organization. The U.S. military has long history of purchasing products with the highest level of ergonomic design. Packaging Products pitched and won the contract to provide high-density foam for the shoulder straps and a weight-lifter style belt for the backpack worn by Marines and other divisions of the military.

Using 1.75# Urethane, we created a spring cushioning effect under the straps so that when the wearers are running, marching or walking, they are protected from shock or injury. For the waist belt, we used 3.1 EVA cross linked foam. As a result of the product’s ability to withstand friction, the shoulders and lower back areas are protected. Our product enables users to perform at a higher level for a longer period of time. Packaging Products was able to deliver on the demand for ergonomics, performance and protection at a lower price than the previous supplier When Irish dancers tap and stomp on a dance floor, it can cause serious and long-term injury to both feet and joints.

Packaging Products was recruited to provide foam cushioning for professional dance companies that move from city to city. The 2-pound cross linked foam features spring cushioning that has been proven to extend professional careers up to 10 years. For this project, we were able to deliver a shorter lead-time and lower pricing. Our cushioned dance floors are in use today nationwide. Packaging Products Inc.’s (PPI) Minority Business Enterprise certification in 2015, opened the door to a new world of networking and resources. One of these resources was the Michigan Minority Supplier Development council (MMSDC). MMSDC believes in the four pillar methodology (Certify-Develop-Connect-Advocate), which led PPI to join the Minority Business Enterprise Input committee (MBEIC). The GEPT concept was introduced to PPI and help navigate PPI’s success story. The following points out how each facet of the GEPT process was leveraged.

GATHER (Layout vision) PPI set a goal to increase sales by targeting automotive production parts business EXPOSE (Use all available opportunities) PPI optimized free memberships and discounted training PREPARE Develop business through contacts made and ISO 9001:2015 certification completed TARGET (Plan of Action) Transfer plan was successfully completed, resulting in increased sales and business opportunities PPI’s success story includes an opportunistic meeting in early 2016 with Greg Harris (Vitec-Global Automotive Alliance) at the AIAG office. Greg asked Larry Flory (PPI CEO) if he planned to take advantage of the FREE five year AIAG membership program available to MBE manufacturing companies under $20M in sales. PPI utilized the cost savings of the membership and discounted training fees to enroll three of its employees into six ISO9001:2015 related courses (APQP, FEMA,SPC and MSA) Utilizing the knowledge and networking connections made though AIAG training, PPI was able to embark onto the next step of ISO9001:2015 certification. PPI has participated in numerous MBE community networking events. Through these connections, PPI obtained recommendations for several ISO9001:2015 consultants. PPI assigned one of their AIAG trained employees to work with a consultant to prepare for ISO9001:2015 certification, which was obtained just 4 months later. PPI's ISO9001:2015 certification along with their MBE certification put them in a unique position to satisfy the Tier 1 automotive supplier needs for both gaskets and custom fit foam solutions. They were able to obtain automotive product part business for the Ford P552 program in 2016. PPI supplied four soft crushed rubber gaskets for the program, which represented about a $3M annual sales gain. These parts were supplied with zero defects and 100% on time delivery. In addition to the increased business, many valuable introductions and connections were made throughout the year, which presents PPI with a multitude of new business opportunities for 2017. PPI would like to thank both MSDC and AIAG for assisting in their company’s supply chain automotive production parts evolution. |